Manufacturing AI UAE: Optimize Production with Predictive Maintenance & Quality Control Automation

Predictive maintenance to prevent equipment failures

Quality control automation with computer vision

Real-time production optimization and scheduling

Supply chain demand forecasting and planning

Automated defect detection on assembly lines

Predictive maintenance to prevent equipment failures

Quality control automation with computer vision

Real-time production optimization and scheduling

Supply chain demand forecasting and planning

Automated defect detection on assembly lines

Predictive maintenance to prevent equipment failures

Quality control automation with computer vision

Real-time production optimization and scheduling

Supply chain demand forecasting and planning

Automated defect detection on assembly lines

Energy consumption optimization across facilities

Inventory management with AI-driven insights

Worker safety monitoring and hazard detection

Process parameter optimization for efficiency

Digital twin simulations for production planning

Energy consumption optimization across facilities

Inventory management with AI-driven insights

Worker safety monitoring and hazard detection

Process parameter optimization for efficiency

Digital twin simulations for production planning

Energy consumption optimization across facilities

Inventory management with AI-driven insights

Worker safety monitoring and hazard detection

Process parameter optimization for efficiency

Digital twin simulations for production planning

Robotic process automation for repetitive tasks

Supplier quality prediction and risk assessment

Production yield optimization with ML models

Equipment performance analytics and diagnostics

Warehouse automation and logistics optimization

Robotic process automation for repetitive tasks

Supplier quality prediction and risk assessment

Production yield optimization with ML models

Equipment performance analytics and diagnostics

Warehouse automation and logistics optimization

Robotic process automation for repetitive tasks

Supplier quality prediction and risk assessment

Production yield optimization with ML models

Equipment performance analytics and diagnostics

Warehouse automation and logistics optimization

Challenge 1: Equipment Downtime Crisis in UAE Manufacturing

Manufacturing facilities across Dubai and UAE face critical production losses from unplanned equipment downtime. A single production line failure costs AED 50,000-200,000 per hour in lost production, delayed customer deliveries, and emergency repair costs. UAE manufacturers report average downtime of 120 hours per month (5 days), equivalent to 17% production capacity loss. Traditional reactive maintenance strategies can't predict failures, resulting in catastrophic breakdowns during peak production periods. Manufacturing AI Dubai predictive maintenance solutions reduce unplanned downtime by 50% through early failure detection.

Unplanned Downtime Costing UAE Manufacturers Millions

Equipment failures across JAFZA and Dubai Industrial City cause AED millions in lost revenue. Average downtime of 120 hours/month equals 17% capacity loss. Our AI predicts failures 7-14 days ahead, reducing downtime by 50% and saving AED 2M+ annually.

Quality Control Issues Impacting UAE Manufacturing Reputation

Manual inspection misses 15-20% of defects, costing AED 500K-2M annually in rework and returns. Our computer vision inspects 100% of products at production speed with 99.5% accuracy, reducing quality costs by 30%.

Supply Chain Disruptions Affecting Dubai Manufacturing

Poor forecasting causes stockouts or excess inventory tying up AED millions in capital. UAE manufacturers rely heavily on imported components. Our AI predicts material needs 30-90 days ahead with 92% accuracy, preventing stoppages.

Challenge 2: Operational Blind Spots Limiting UAE Manufacturing Performance

Without real-time visibility into equipment health, quality metrics, energy consumption, and production efficiency, UAE manufacturers operate reactively rather than proactively. Critical performance indicators remain unknown until monthly reports, by which time millions in optimization opportunities have been missed. Manufacturing AI Dubai provides real-time dashboards showing OEE, quality trends, energy usage, and predictive alerts that enable data-driven decisions increasing profitability by 15-20%.

Data Silos Preventing Production Optimization in UAE Facilities

Data silos across MES, ERP, and SCADA systems prevent optimization and bottleneck identification. Our AI integrates all systems for real-time visibility, enabling decisions that increase OEE by 25%.

Manual Scheduling Limiting UAE Production Capacity

Manual scheduling creates bottlenecks and missed deadlines as manufacturers balance multiple orders and constraints. Our AI optimizes production sequences, reducing lead times by 20% and improving on-time delivery to 98%.

Reactive Maintenance Driving Higher Costs in UAE Manufacturing

Reactive maintenance leads to catastrophic failures, 72-hour downtimes, and 40% higher costs from emergency repairs. Our predictive approach shifts to proactive scheduling, cutting costs by 35% and eliminating 90% of failures.

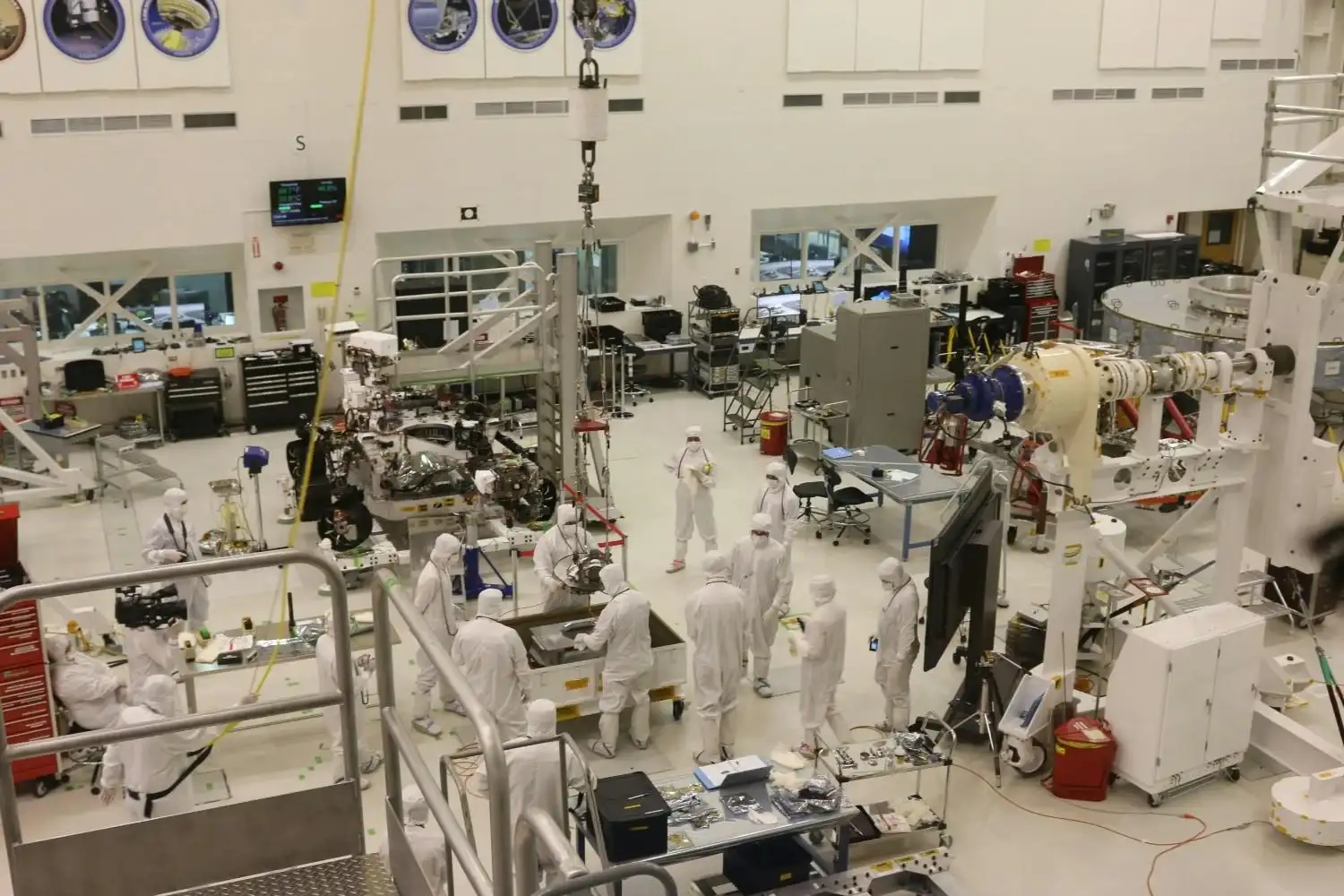

AI in Manufacturing

Strategic use cases we deliver

Predictive Maintenance for UAE Manufacturing Facilities

Predict equipment failures 7-14 days in advance with 95% accuracy. Our AI analyzes sensor data and maintenance records to schedule proactive repairs, reducing downtime by 50% and cutting costs by 35%.

Automated Quality Control for Smart Manufacturing UAE

Inspect products at full production speed with 99.5% accuracy using computer vision. We detect defects invisible to human inspectors, reducing quality costs by 30% and eliminating 95% of customer returns.

Production Optimization for Industry 4.0 Dubai Factories

Optimize production schedules and parameters in real-time to maximize throughput. Our AI increases OEE by 25%, reduces energy costs by 18%, and improves on-time delivery to 98% for Dubai manufacturers.

Supply Chain Intelligence for UAE Manufacturing Operations

Forecast demand with 92% accuracy and optimize inventory automatically. Our AI predicts supply chain disruptions before they occur, reducing inventory costs by 25% and preventing 90% of production stoppages.

Our Manufacturing AI Capabilities

We don't just build software; we engineer intelligence. Our services are designed to help organizations navigate the complexities of modern AI adoption.

From initial consultation to full-scale deployment, we partner with you to create AI solutions that drive measurable business outcomes and sustainable growth.

Why Choose Mirchandani for Manufacturing AI Dubai

Innovation

The right Manufacturing AI Dubai partner doesn't just deliver technology - we increase production efficiency, reduce costs, and transform UAE manufacturing operations with proven Industry 4.0 solutions.

Manufacturing Industry Expertise in UAE Market

Deep understanding of UAE manufacturing across JAFZA, KIZAD, and Dubai Industrial City with proven expertise in OSHAD, DEWA, and Emirates Quality Mark compliance.

Proven ROI in Smart Manufacturing UAE

50% less downtime, 30% better quality, 25% higher OEE, and 35% lower maintenance costs. Average ROI achieved within 6-9 months for UAE facilities.

Secure & Scalable for 24/7 UAE Operations

99.9% uptime for 24/7 operations with secure integration to MES, ERP, and SCADA systems. Scalable from single line to multi-facility deployment.

End-to-End Partnership for Industry 4.0 Transformation

Complete support from pilot to full deployment with 24/7 UAE-based team responding in under 2 hours. Includes comprehensive training and continuous optimization.

Dozens of AI-Powered Tools for Manufacturing

From predictive analytics to intelligent automation, explore our comprehensive suite of AI solutions.

Automated Visual Quality Control for UAE Manufacturing

Deploy computer vision systems that inspect products at full production speed with 99.5% accuracy. Detect surface defects, dimensional variations, and assembly errors instantly for pharmaceutical, aerospace, and food & beverage manufacturing in KIZAD and JAFZA. Our Manufacturing AI Dubai quality control solution eliminates human inspection fatigue and error, processing 1000+ units per minute while catching micro-defects invisible to the naked eye. Perfect for UAE pharmaceutical manufacturers requiring GMP compliance, automotive parts suppliers needing zero-defect quality, and food production facilities maintaining ESMA standards. Reduces quality control costs by 60%, eliminates customer returns by 95%, and ensures Emirates Quality Mark certification compliance across all Dubai Industrial City and JAFZA production facilities.

Inspect product surface for micro-defects and scratches

Manufacturing AI Questions

Common questions about AI solutions for UAE manufacturing facilities

How does predictive maintenance AI reduce downtime in UAE factories?

Predictive maintenance AI monitors machinery in real-time using IoT sensors, predicting failures 2-4 weeks in advance with 88% accuracy. UAE manufacturers in Jebel Ali and KIZAD have reduced unplanned downtime by 50% and maintenance costs by 30%, preventing costly production disruptions and extending equipment lifespan.

What is the implementation cost for manufacturing AI in Dubai?

Implementation costs vary based on facility size and complexity, typically ranging from AED 500,000 to AED 2 million for mid-sized UAE manufacturing operations. ROI is typically achieved within 12-18 months through reduced downtime, improved quality control, and optimized resource utilization. We offer flexible deployment models including cloud-based solutions.

How does AI improve quality control in UAE manufacturing facilities?

Computer vision AI inspects products at rates of 100+ items per minute with 99.5% defect detection accuracy, far exceeding manual inspection (85-90% accuracy). Dubai manufacturers have reduced defect rates by 60%, decreased customer returns by 45%, and achieved significant cost savings through early defect detection and automated quality assurance.

Can AI integrate with existing factory automation systems?

Yes, our manufacturing AI integrates seamlessly with PLCs, SCADA systems, MES platforms, and ERP systems commonly used in UAE factories. We support protocols like OPC UA, MQTT, and Modbus, ensuring smooth integration with legacy equipment while adding advanced AI capabilities for real-time optimization and predictive insights.

How does AI optimize supply chain operations for UAE manufacturers?

AI analyzes demand patterns, supplier performance, and market conditions to optimize inventory levels, reducing holding costs by 25% while preventing stockouts. UAE manufacturers using our solutions have improved order fulfillment rates by 35%, reduced lead times by 40%, and achieved better coordination with Dubai ports and logistics partners.

What energy savings can manufacturers achieve with AI optimization?

AI-powered energy management systems reduce manufacturing energy consumption by 20-30% through real-time optimization of HVAC, lighting, and production schedules. UAE factories have achieved annual savings of AED 1-2 million while supporting Dubai's Clean Energy Strategy 2050 and reducing carbon emissions by up to 25%.

How does AI support smart factory transformation in Dubai?

AI enables complete smart factory transformation through digital twin technology, real-time production optimization, autonomous quality control, and predictive analytics. UAE manufacturers implementing Industry 4.0 with our AI solutions have achieved 40% productivity improvement, 50% faster time-to-market, and 35% reduction in operational costs.

What training do factory workers need to operate AI systems?

Factory workers typically require 3-5 days of hands-on training covering AI system operation, alert interpretation, and basic troubleshooting. We provide bilingual training in Arabic and English, intuitive dashboards, and ongoing support. Most operators become proficient within 2 weeks, with AI augmenting rather than replacing their expertise.

How does predictive maintenance AI reduce downtime in UAE factories?

Predictive maintenance AI monitors machinery in real-time using IoT sensors, predicting failures 2-4 weeks in advance with 88% accuracy. UAE manufacturers in Jebel Ali and KIZAD have reduced unplanned downtime by 50% and maintenance costs by 30%, preventing costly production disruptions and extending equipment lifespan.

What is the implementation cost for manufacturing AI in Dubai?

Implementation costs vary based on facility size and complexity, typically ranging from AED 500,000 to AED 2 million for mid-sized UAE manufacturing operations. ROI is typically achieved within 12-18 months through reduced downtime, improved quality control, and optimized resource utilization. We offer flexible deployment models including cloud-based solutions.

How does AI improve quality control in UAE manufacturing facilities?

Computer vision AI inspects products at rates of 100+ items per minute with 99.5% defect detection accuracy, far exceeding manual inspection (85-90% accuracy). Dubai manufacturers have reduced defect rates by 60%, decreased customer returns by 45%, and achieved significant cost savings through early defect detection and automated quality assurance.

Can AI integrate with existing factory automation systems?

Yes, our manufacturing AI integrates seamlessly with PLCs, SCADA systems, MES platforms, and ERP systems commonly used in UAE factories. We support protocols like OPC UA, MQTT, and Modbus, ensuring smooth integration with legacy equipment while adding advanced AI capabilities for real-time optimization and predictive insights.

How does AI optimize supply chain operations for UAE manufacturers?

AI analyzes demand patterns, supplier performance, and market conditions to optimize inventory levels, reducing holding costs by 25% while preventing stockouts. UAE manufacturers using our solutions have improved order fulfillment rates by 35%, reduced lead times by 40%, and achieved better coordination with Dubai ports and logistics partners.

What energy savings can manufacturers achieve with AI optimization?

AI-powered energy management systems reduce manufacturing energy consumption by 20-30% through real-time optimization of HVAC, lighting, and production schedules. UAE factories have achieved annual savings of AED 1-2 million while supporting Dubai's Clean Energy Strategy 2050 and reducing carbon emissions by up to 25%.

How does AI support smart factory transformation in Dubai?

AI enables complete smart factory transformation through digital twin technology, real-time production optimization, autonomous quality control, and predictive analytics. UAE manufacturers implementing Industry 4.0 with our AI solutions have achieved 40% productivity improvement, 50% faster time-to-market, and 35% reduction in operational costs.

What training do factory workers need to operate AI systems?

Factory workers typically require 3-5 days of hands-on training covering AI system operation, alert interpretation, and basic troubleshooting. We provide bilingual training in Arabic and English, intuitive dashboards, and ongoing support. Most operators become proficient within 2 weeks, with AI augmenting rather than replacing their expertise.